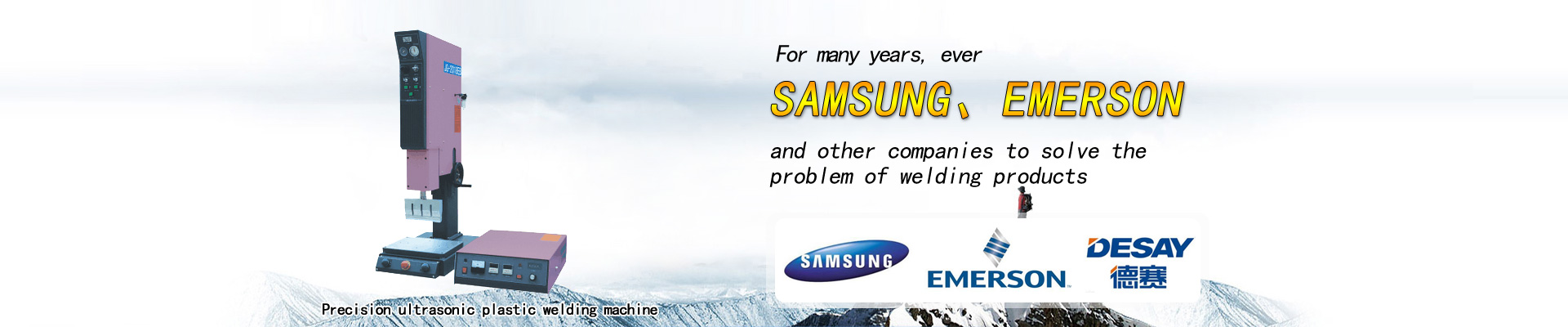

Shenzhen City, the structure of the ultrasonic welding machine

This machine is composed of ultrasonic generator, ultrasonic transducer system, program control and pneumatic rack system.

A: the name of the component (see Figure 1)

(1) the lifting speed (2) of the welding time (3)

(4) pressure gauge (5) pressure gauge (6) ultrasonic testing switch

(7) head lifting switch (8) trigger switch mechanism (9) separator

(10) fixed handle (11) of the body () of the lifting wheel (12).

(13) (14) two transducer fixed screw rod (15) head

(16) trigger switch (17) emergency stop switch (18) limit bolt

(20) power switch (21) overload indicator (22) ultrasonic testing switch

(23) load current meter (24) frequency modulation inductance (25) radiating air outlet

(26) control socket (27) ultrasonic output socket (28) fuse holder

(29) power supply line entrance (30) amplitude adjustment switch

B: component name and function

(1): the lifting speed adjusting knob can adjust the welding head on the speed, acceleration and deceleration, clockwise rotation.

(2) welding time: this knob is a band switch, it is an adjustable resistance, adjusting the time of ultrasonic welding.

(3) the time of holding pressure: the same as the welding time knob, used to adjust the time of curing of the plastic parts after the ultrasonic emission.

(4) air pressure gauge: indicating the working pressure.

(5): pressure regulator for regulating the working pressure, will pull the knob can be adjusted, after a good tune can be pressed into the.

(6) ultrasonic test switch: touch switch, you can send the ultrasonic, generally used for ultrasonic examination is normal.

(7) head lifting switch: mainly used for checking mould, the switch is a self-locking switch, press to press recovery.

(8) the trigger switch mechanism is used to control the trigger of an ultrasonic wave, such as the time relay, which indicates the delay time between the trigger and the ultrasonic wave.

(9) manifolds: for separation of compressed air in the water, please in the water is half full cup will be the end of the needle upward pressure to drain the water.

(10) body fixed handle: used for fixing the upper frame.

(11) lift hand wheel: (10) can be adjusted to adjust the frame height.

(12) the transducer is fixed: for a fixed transducer system.

(13) fixed screw transducer:

(14) two lever: also known as an amplifier for amplifying the output amplitude of the transducer.

(15): also called welding welding mold, the ultrasonic energy transmitted to the workpiece. Usually for a half wavelength of the resonant frequency, material for titanium alloy and aluminum alloy, aluminum alloy welding head to work leaving the oxide can be plating or the use of heat plastic membrane to prevent.

* Note * welding head can not modify any, otherwise it will change its resonant frequency and the mechanical strength, easy to cause damage to the transducer and electrical parts.

(16) the trigger switch is triggered at the same time, the normal procedure can be realized.

(17) emergency stop switch: switch to the self-locking switch, a trigger, it couldn't fall head. Such as the trigger after the reset knob, easy to program operation.

(18) limit bolt: bolt position adjusting nut, welding head can limit the drop height, plastic welding depth control.

(20) power switch: after the switch is turned on, the power supply is turned on, the indicator light is on, the fan starts to run.

(21) overload indicator: when the abnormal machine ultrasonic vibration, the vibration and stop light exhibit of lanterns.

(22) the ultrasonic test switch: the trigger is an ultrasonic wave, which is used to test whether the sound is normal or not.

(23) load current meter: no load, degree of the resonance of the horn, (pointer is lower better, depending on the welding head and the output section number, usually between 5% to 15% or 300MA~900MA) load said the size of the output power. (depending on the workpiece).

(see next page)

(24) FM inductance: the working frequency of the regulator circuit is matched with the resonance frequency of the mechanical vibration. (step by step, please refer to the operation tips.)

(26) control socket: the use of cable connection, transmission control loop signal.

(27) ultrasonic output plug: the use of cable connection, high voltage electric signal transmission to the transducer.

(28) the fuse holder: a fuse.

(30) amplitude modulation switch: selected appropriate welding output amplitude, to match the requirements of the work, the switch only 1.2.3 third gear, and all the rest to the neutral gear and only 15KHz models.